| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary three-piece clamp is a high-cleanliness connector, consisting of two symmetrical clamps and a locking bolt, which is used to quickly connect and fix sanitary pipes to achieve efficient assembly of sterile fluid delivery systems. The stainless steel sanitary three-piece clamp is used for sanitary pipes in the food, pharmaceutical, biotechnology and other industries. It is usually installed at the pipe joint, valve interface or equipment inlet and outlet to achieve quick disassembly and assembly, ensure sealing, and facilitate cleaning and maintenance, thereby improving production efficiency and hygiene standards. Common types of stainless steel sanitary three-piece clamps include: standard type, quick disassembly type, double seal type, flushing port type, flange type, and gasket type.

JONENG

8481804090

Stainless Steel High Performance Adjustable Three-piece Pipe Clamp

The purpose of the stainless steel sanitary three-piece clamp design is to provide a reliable and efficient connection method in fluid delivery systems that require high hygiene standards. It uses a three-piece structure to ensure that the process of pipe disassembly and cleaning is simplified while maintaining sealing. This design can avoid the leakage problem that may be caused by frequent disassembly of traditional clamps, adapt to the CIP/SIP automatic cleaning requirements, and improve the continuity and hygiene management level of the production line. Especially in the transportation environment of high temperature, high pressure and highly corrosive media, it shows unique stability and durability.

Working Principles

The working principle of the stainless steel sanitary three-piece clamp is based on a three-piece structure, connecting the equipment or pipes at both ends of the pipe together through two symmetrical clamps and a locking bolt. When the bolt is tightened, the clamp tightly presses the pipe and the sealing gasket to ensure a leak-proof seal while providing a firm fixing force. The clamp design allows for quick disassembly and installation, making the connection between equipment simple and efficient. It is widely used in sanitary piping systems to meet high cleanliness requirements and supports CIP/SIP cleaning to maintain a sterile environment during fluid delivery.

The options for the stainless steel sanitary three-piece clamp include:

Material: 304 stainless steel, 316L stainless steel

Sealing gasket: EPDM, PTFE, silicone

Connection method: quick disassembly, flange connection

Surface treatment: mirror polishing, electrolytic polishing

Size: A variety of pipe sizes are available

Pressure level: Adapt to different pressure environments

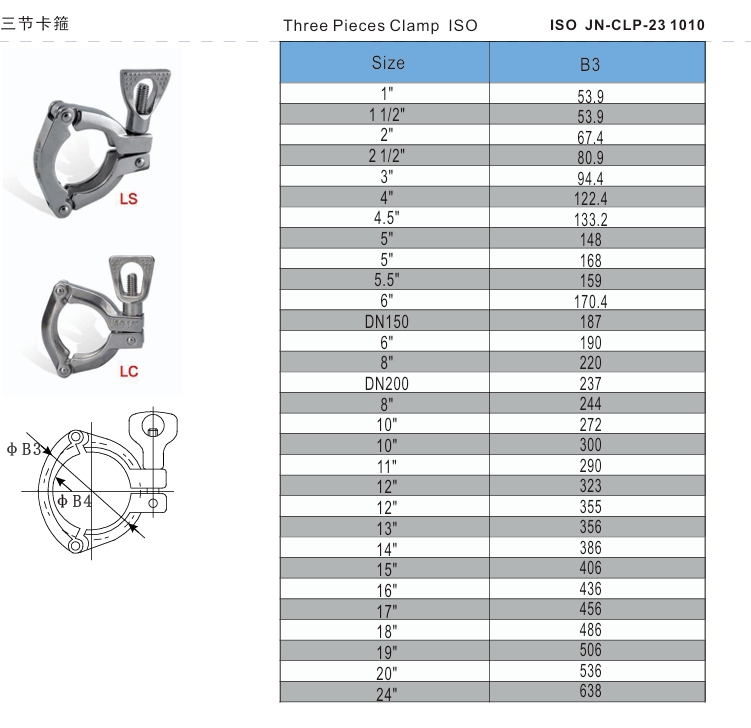

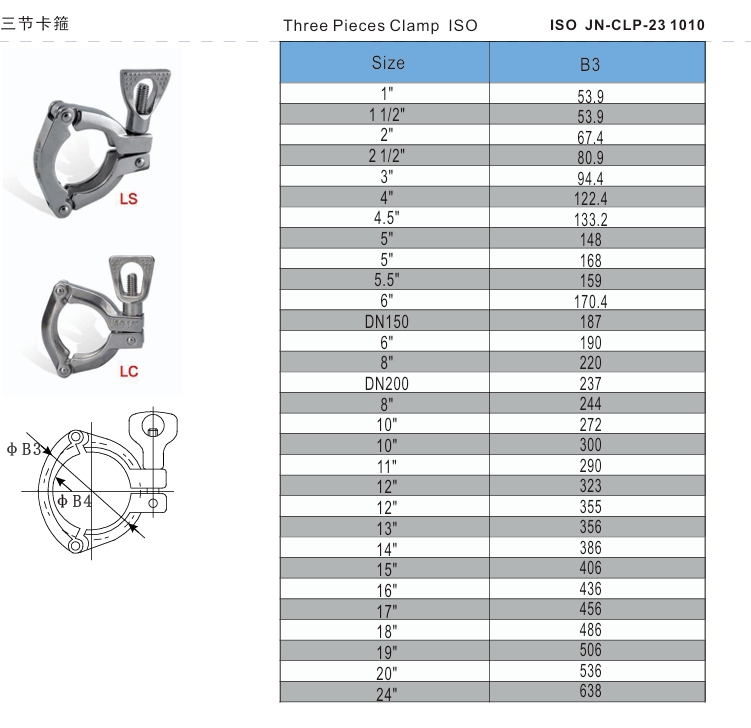

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201,SS201 |

Gasket | Silicone, PTFE, EPDM, viton |

Made from precise casting | |

Features

● The three-piece structure of the stainless steel sanitary three-piece clamp can provide more uniform pressure distribution, ensure that the clamp can firmly fix the pipe, and avoid leakage or instability caused by uneven connection.

● The precision slot design between the stainless steel sanitary three-piece clamp and the sealing gasket ensures better sealing effect and reduces the leakage and loosening problems that may occur in conventional clamps.

● The stainless steel sanitary three-piece clamp adopts locking bolt and spring design to achieve quick disassembly and installation, reduce equipment maintenance time, and increase the flexibility and operating efficiency of the production process.

● The stainless steel sanitary three-piece clamp provides a larger contact area to ensure that the sealing gasket can effectively fit the pipe surface, improve the sealing performance, and prevent liquid or gas leakage.

● The surface of the stainless steel sanitary three-piece clamp is processed and polished with high precision to improve wear resistance and reduce damage caused by friction during long-term use.

● The stainless steel sanitary three-piece clamp structure is optimized to withstand higher loads, suitable for heavy equipment or long-term working scenes, and provide stable connection.

Application

Stainless steel sanitary three-piece clamps are used in the following industries: Food processing: used for fluid transportation to ensure no pollution. Pharmaceutical industry: to ensure the hygiene of the drug production environment. Dairy industry: to connect production equipment to ensure hygiene. Cosmetics industry: avoid contamination of raw materials. Biotechnology: for sterile fluid systems. Chemical production: prevent leakage and contamination.

Working Principles

The working principle of the stainless steel sanitary three-piece clamp is based on a three-piece structure, connecting the equipment or pipes at both ends of the pipe together through two symmetrical clamps and a locking bolt. When the bolt is tightened, the clamp tightly presses the pipe and the sealing gasket to ensure a leak-proof seal while providing a firm fixing force. The clamp design allows for quick disassembly and installation, making the connection between equipment simple and efficient. It is widely used in sanitary piping systems to meet high cleanliness requirements and supports CIP/SIP cleaning to maintain a sterile environment during fluid delivery.

The options for the stainless steel sanitary three-piece clamp include:

Material: 304 stainless steel, 316L stainless steel

Sealing gasket: EPDM, PTFE, silicone

Connection method: quick disassembly, flange connection

Surface treatment: mirror polishing, electrolytic polishing

Size: A variety of pipe sizes are available

Pressure level: Adapt to different pressure environments

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201,SS201 |

Gasket | Silicone, PTFE, EPDM, viton |

Made from precise casting | |

Features

● The three-piece structure of the stainless steel sanitary three-piece clamp can provide more uniform pressure distribution, ensure that the clamp can firmly fix the pipe, and avoid leakage or instability caused by uneven connection.

● The precision slot design between the stainless steel sanitary three-piece clamp and the sealing gasket ensures better sealing effect and reduces the leakage and loosening problems that may occur in conventional clamps.

● The stainless steel sanitary three-piece clamp adopts locking bolt and spring design to achieve quick disassembly and installation, reduce equipment maintenance time, and increase the flexibility and operating efficiency of the production process.

● The stainless steel sanitary three-piece clamp provides a larger contact area to ensure that the sealing gasket can effectively fit the pipe surface, improve the sealing performance, and prevent liquid or gas leakage.

● The surface of the stainless steel sanitary three-piece clamp is processed and polished with high precision to improve wear resistance and reduce damage caused by friction during long-term use.

● The stainless steel sanitary three-piece clamp structure is optimized to withstand higher loads, suitable for heavy equipment or long-term working scenes, and provide stable connection.

Application

Stainless steel sanitary three-piece clamps are used in the following industries: Food processing: used for fluid transportation to ensure no pollution. Pharmaceutical industry: to ensure the hygiene of the drug production environment. Dairy industry: to connect production equipment to ensure hygiene. Cosmetics industry: avoid contamination of raw materials. Biotechnology: for sterile fluid systems. Chemical production: prevent leakage and contamination.