| Availability: | |

|---|---|

| Quantity: | |

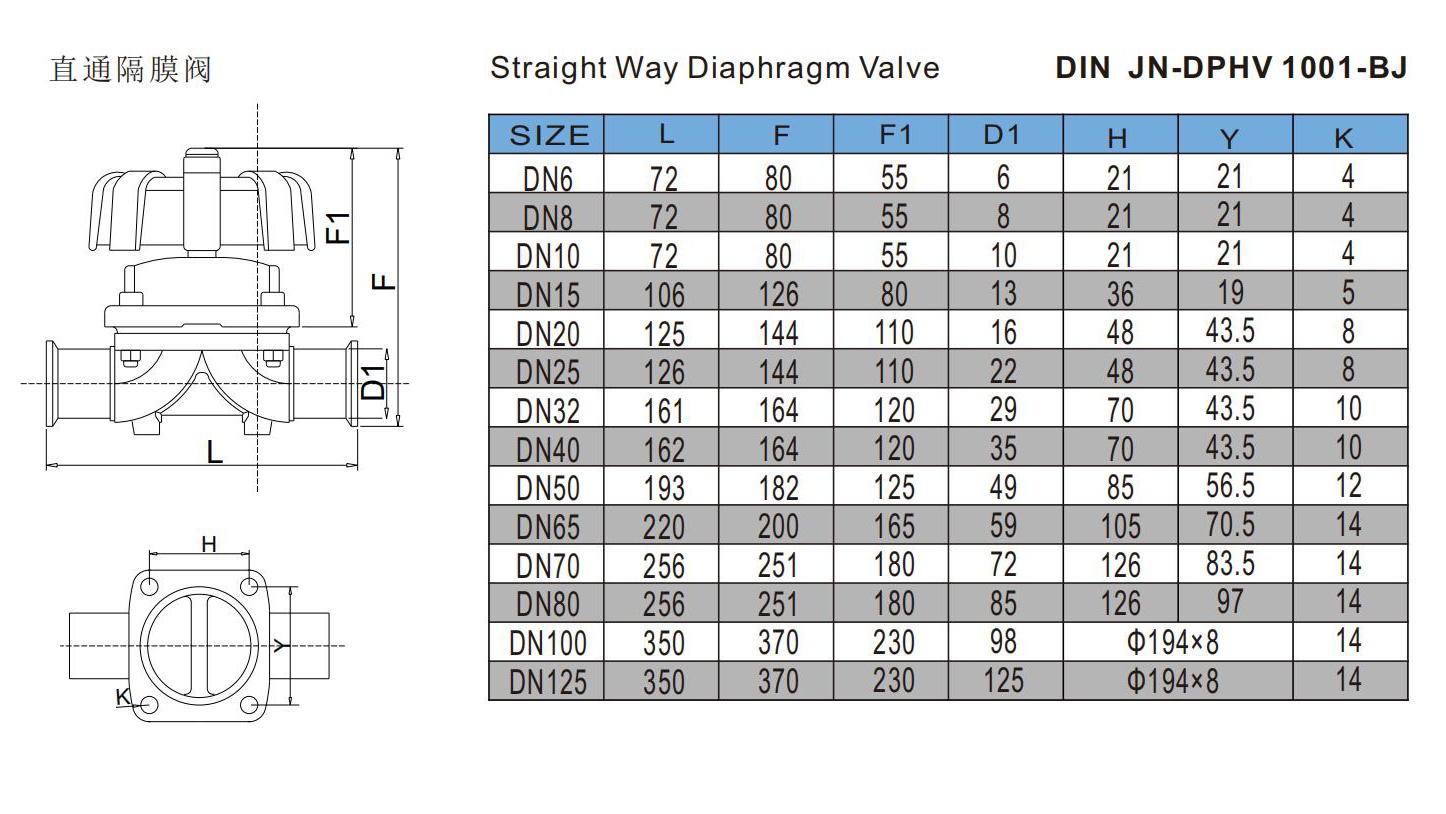

DIN JN-DPHV 1001-BJ

JONENG

8481804090

Stainless Steel Aseptic Clamped Two-way Diaphragm Valve

The sanitary diaphragm valve is remotely controlled by the driving actuator or manually operated by a handle.It has the advantages of simple structure, beautiful appearance, quick disassembly , flexible operation, less fluid resistance, and reliable application, etc.

Working Principles

The sanitary diaphragm valve separates the inner wall of the upper and lower valve body of the diaphragm, so that the valve stem, valve disc and other parts above the diaphragm are not corroded by the medium, the structure of packing seat assures there is no-medium leakage. It not only ensures the purity of the working medium in the pipeline, but also prevents the medium from the working parts in the pipeline. In a diaphragm valve, since the working medium is only in contact with the diaphragm and the valve body, both of which are the food grade FDA approved. The valve can ideally control a variety of working mediums, especially those with chemical corrosion working medium.The diaphragm valve body and gasket with the tight fit to provide the valve body seal and seat seal to ensure the pipeline inside and outside environment completely isolated.

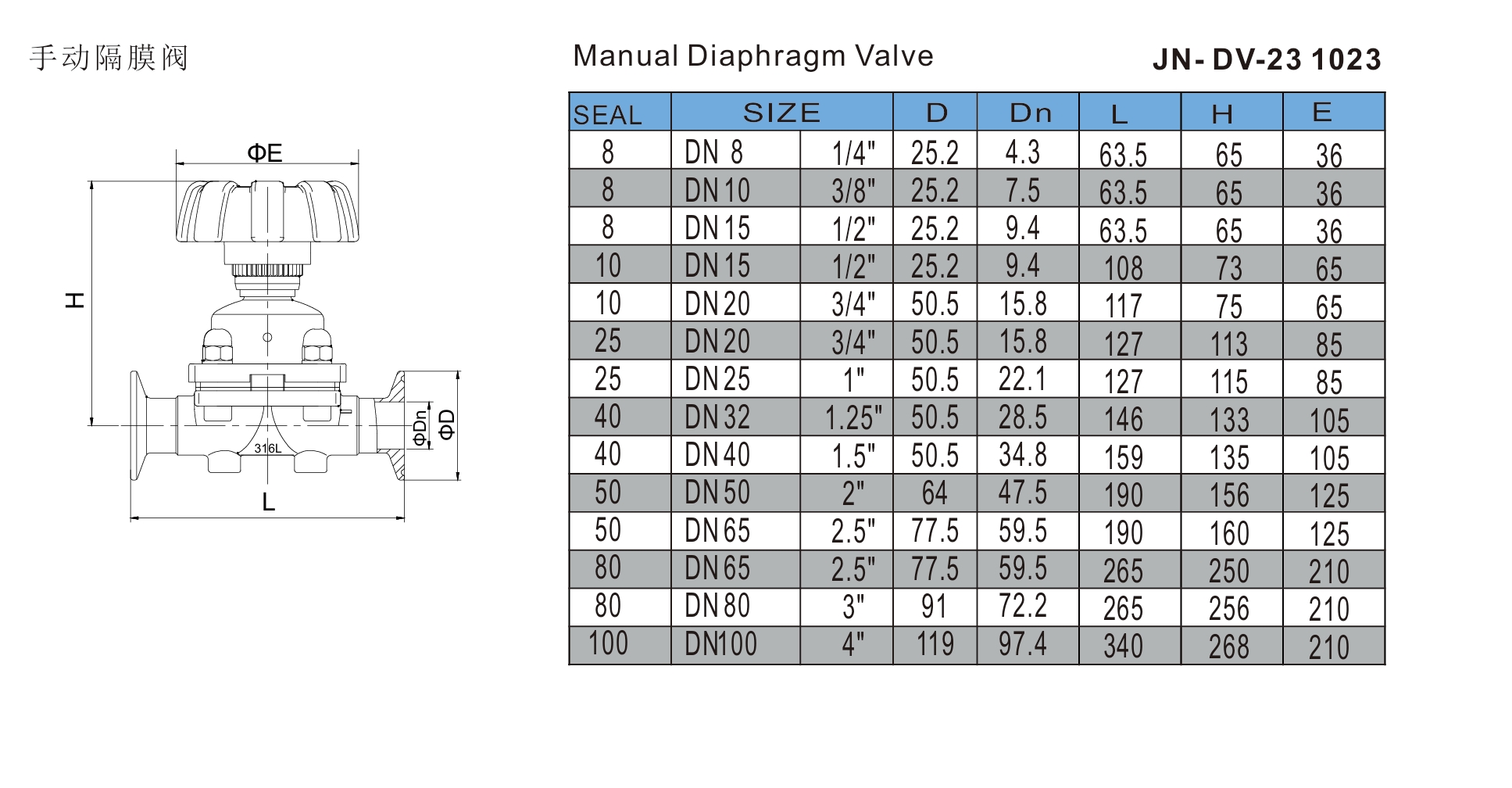

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

● Unique seal design, no dead angles

● Absolutely sterile, no blind corner.

● Stainless steel bonnet with sanitary internals

● 100% hydraulic tested / 100% inspected

● Gentle material handling

● Diaphragm 300000 times test

● Diaphragm perfect match the valve body design

● Valve operation more safe and efficient

● The inner surface is RA0.4, which fully conforms to the pharmaceutical grade

● Excellent for flow control,Straight through flow path

● Easy disassembly, easy maintainenance, easy to clean, CIP

● Low turbulence, Minimal back pressure

●Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

Diaphragm valves, manually or pneumatically operated, are specifically designed for use in sanitary and aseptic processes in the medical and pharmaceutical industries. Very good performance in controlling the flow rate of the small flow piping line. The valves are suitable for applying in high flow rate, high corrosivity, high viscosity fluid.

Working Principles

The sanitary diaphragm valve separates the inner wall of the upper and lower valve body of the diaphragm, so that the valve stem, valve disc and other parts above the diaphragm are not corroded by the medium, the structure of packing seat assures there is no-medium leakage. It not only ensures the purity of the working medium in the pipeline, but also prevents the medium from the working parts in the pipeline. In a diaphragm valve, since the working medium is only in contact with the diaphragm and the valve body, both of which are the food grade FDA approved. The valve can ideally control a variety of working mediums, especially those with chemical corrosion working medium.The diaphragm valve body and gasket with the tight fit to provide the valve body seal and seat seal to ensure the pipeline inside and outside environment completely isolated.

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

Max. working pressure | 10 Bar |

Temperature range | -10° ~ +120°C or higher upon request |

Sizes available | 1" to 6" |

End connection | Clamp, Weld, Flange, Thread |

Body material | AISI 316L |

Body structure | 2 way, 3-way, Casting Tee type,U type,Forged Tee type, with draining port, Non dead leg diaphragm block valves |

Seal material | Single diaphragm EPDM,EPDM+PTFE bounded membrane , EPDM/PTFE 2pieces membrane |

Operation | plastic or stainless hand wheel,Pneumatic plastic actuator,Pneumatic stainless steel actuator, Electric actuator |

Surface treatment | Ra 0.4 ~ 0.8µm |

Standards | 3A, SMS, DIN, ISO |

Features

● Unique seal design, no dead angles

● Absolutely sterile, no blind corner.

● Stainless steel bonnet with sanitary internals

● 100% hydraulic tested / 100% inspected

● Gentle material handling

● Diaphragm 300000 times test

● Diaphragm perfect match the valve body design

● Valve operation more safe and efficient

● The inner surface is RA0.4, which fully conforms to the pharmaceutical grade

● Excellent for flow control,Straight through flow path

● Easy disassembly, easy maintainenance, easy to clean, CIP

● Low turbulence, Minimal back pressure

●Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

Diaphragm valves, manually or pneumatically operated, are specifically designed for use in sanitary and aseptic processes in the medical and pharmaceutical industries. Very good performance in controlling the flow rate of the small flow piping line. The valves are suitable for applying in high flow rate, high corrosivity, high viscosity fluid.